Hydrogen I Our solutions

Converters for green hydrogen production

The green hydrogen challenge

The goal of reducing global CO2 emissions to net zero by 2050 is consistent with efforts to limit the long-term increase in average global temperatures by 1.5˚C.

In this path, hydrogen stands for the core of change by being a central topic in political, energy and industrial debates.

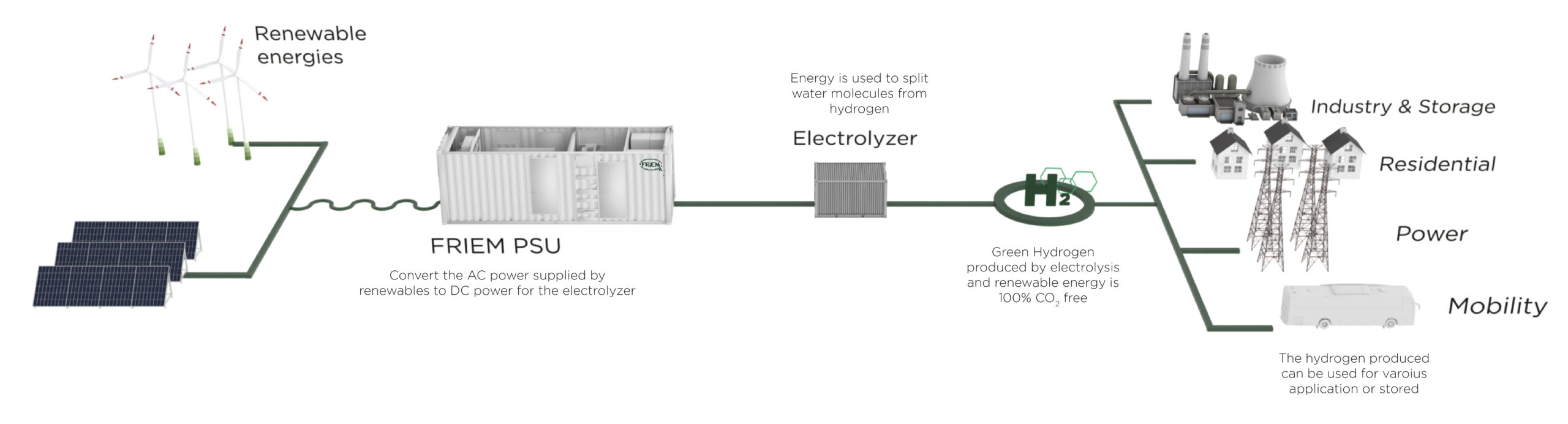

Counting on the huge know-how FRIEM has in in the energy conversion, we play a key role between renewables and end users in the green hydrogen supply chain. We supply the rectifier and all the equipment for the converters for green hydrogen production.

Our Solutions

Completely assembled and wired units to reduce the time taken for installation and commissioning on site

Owing to the installation of a dedicated solution (e.g., harmonic filters) to improve the power factor and THD on the supply voltage grid

Our service team (deployed worldwide) will support our customers along the years also through tailored maintenance programs

The installation of high-quality equipment and the design factors arising from our long-term experience ensures high performance

Easy access to all the components within the Power Supply Unit (PSU) to allows proper space for maintenance activities

Optimised to fit the toughest site constraints thanks to a flexible and efficient design.

Learn how we support the energy transition

Transforming the energy of tomorrow

Governments worldwide are very keen interested on learning methods for reducing the net emissions of greenhouse gasses, as well as to develop a national strategy enabled to empower valuable hydrogen supply chains. Hydrogen definitely proves to be decisive in production and energy consumption, as it is versatile and can be integrated into the other clean energies. Green hydrogen production through water electrolysis, will be one of the key methods to support the energy transition. In fact, green hydrogen produced by electrolysis and renewables is 100% CO2-free.

Rectifiers for large scale electrolysis

Robust, efficient and purpose-built, FRIEM PSU (Power Supply Unit) pairs with the main electrolytic cells’ technologies (alkaline, PEM and SOEC). It can be delivered fully equipped with: rectifier transformer, DC no load isolators, thyristor rectifier, automatic harmonic filters, heat exchanger, local control cabinet, polarisation rectifier and cooling cabinet. If required, the PSU can be fully containerised in order to limiting the footprint.

Key concepts

Hydrogen is the first element in the periodic table (symbol H). It is the most abundant and the lightest chemical substance in the universe.

Reforming is the most widespread method to extract hydrogen from natural gas, liquefied petroleum gas and naphtha. Other processes include gasification and electrolysis.

It is when hydrogen is produced by electrolysis of water using electricity produced from renewable energy (wind, solar and hydropower).

Water electrolysis is an electrochemical process that splits water into hydrogen and oxygen.

Hydrogen use today is dominated by the oil refining, ammonia, methanol and steel production industries.

Hydrogen is essential for the decarbonisation of the energy system. It offers ways to decarbonise industrial processes and looks promising as the lowest-cost option for storing electricity; it can also transport energy from renewables over long distances. Lastly, Hydrogen can be used as an energy carrier in sectors hlike transportation, as well as and to heat and power buildings.

Download

FRIEM Converters for green Hydrogen production

Rectifiers for large scale electrolysis

English – March 2021

FRIEM HyCon station

Plug&play solution for green hydrogen production

English – March 2023